For one eye-opening month during college, biomedical engineering student Reece Stevens joined the staff of a remote hospital in Rwanda, where he saw nurses struggling to care for hundreds of patients with only a handful of patient monitors. From that point forward, Stevens became determined to build a new device that could be manufactured less expensively and in higher quantities — one that he felt could change, and potentially save, thousands of lives around the world.

You don’t need to be so far along in your college career to generate good ideas and sound engineering. Anyone can be an inventor.”

Considering that he had never before left the U.S., much less traveled anywhere alone, a two-month journey to another continent was a daunting proposition for both Stevens and his parents. But, after applying and gaining acceptance to the Engineering World Health Summer Institute, a student program aimed at building and repairing medical devices in low-income countries, Stevens had no time to dwell on his own stress and uncertainty. After arriving in Rwanda in June 2014, he quickly learned the basics of the Rwandan language of Kinyarwanda before joining his colleagues for a full month of intensive device-repair training—just the type of hands-on experience he was seeking.

“I had just finished my freshman year and didn’t know anything about in-depth hardware design or fixing complex machines,” Stevens said. “But once you start cracking them open, you learn pretty quickly what to look for and how to recognize what is broken.”

Equipped with this new training, Stevens spent the second month repairing devices for a local hospital, where he experienced first-hand the challenges facing medical providers in developing countries. When he took inventory of the hospital’s equipment, he was disheartened by how quickly he completed the task, so scarce were the hospital’s resources.

“There were 400 beds in the hospital and only five patient monitors,” he said. “I will never forget seeing three patients in critical condition with only one monitor. The nurses were hooking one patient up to the monitor and measuring their vitals, then immediately disconnecting that patient, connecting to the next patient and repeating the process. You can’t perform surgeries without hooking patients up to monitors. I’d see people actually standing in lines that wrapped around the hospital, waiting hours for surgery because of the lack of monitors. It was unbelievable.”

Unable to shake these realities, and certain that lower-cost, readily available monitors could solve the problems he encountered, Stevens began working with his Engineering World Health student group at UT Austin to design a new device that could function in an unsealed environment with no climate control and frequent power outages.

But functionality alone was not enough to address Stevens’ greatest concern. During his 60 days in Rwanda, Stevens noticed a high turnover rate among the nurses and discovered that they frequently move from one hospital to another, bringing their training with them. He realized he needed to develop a monitor that would require minimal training to operate. Borrowing a phrase from Steve Jobs, he wanted to make a device that “just works.”

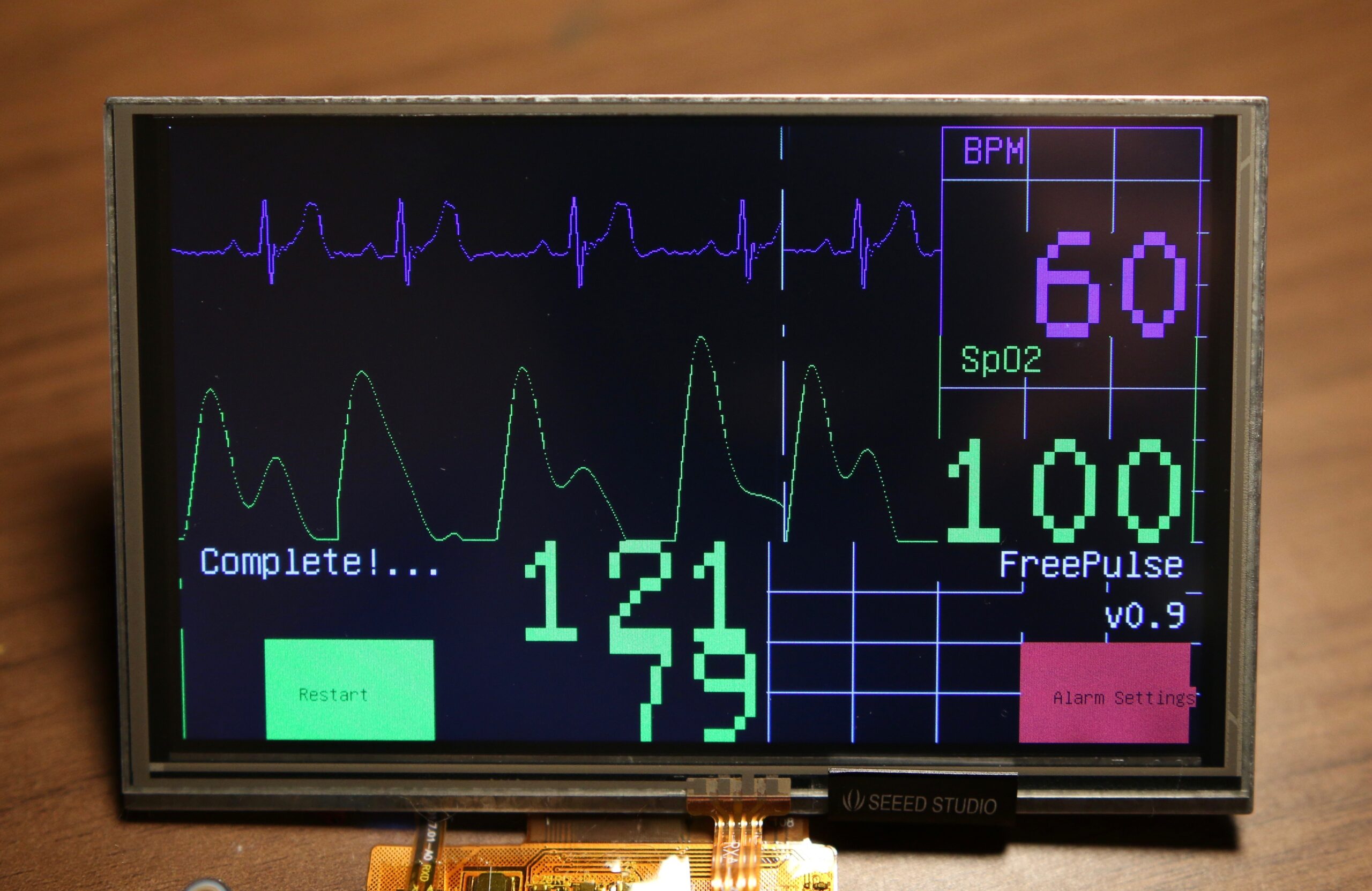

That sentiment became the guiding mandate of FreePulse, the social venture project that Stevens launched upon his return for the development of this new monitor. Initial designs outlined a simple touchscreen device with no buttons that ran on batteries and only measured EKG. Most importantly, it just worked.

We didn’t have many tools … I had a knife and some epoxy, and I was gluing stuff together on bumpy jeep rides to keep it intact.”

The prototype was well received at engineering design competitions in 2015, taking first place in the international Engineering World Health Design Competition and second place in the prestigious National Institutes of Health Design by Biomedical Undergraduate Teams Challenge. The immediate success surprised Stevens and his teammates. “Most of us were only sophomores,” he recalls, “so it was encouraging to realize that you don’t need to be so far along in your college career to generate good ideas and sound engineering. Anyone can be an inventor.”

Despite the accolades, Stevens was unsatisfied with the device’s limited functionality and began developing a second prototype from scratch that could measure pulse oximetry, which detects changes in blood oxygen levels. He also incorporated an arm cuff for measuring blood pressure.

As it turns out, one of the few things that Rwandan hospitals have in abundance are sphygmomanometers, old-fashioned blood pressure measurement devices that are inaccurate and difficult to use. But by modifying his device to work with standard cuffs pulled from these sphygmomanometers, Stevens created a device that will allow nurses to more easily utilize the equipment they have on hand.

Ultimately, Stevens hopes to make every function compatible with the equipment he inventoried in Rwanda. “We had several clear goals for this device that we thought would make it successful: make it work with what’s on hand, don’t make it difficult for the end user, make it battery-powered and easy to read, and make sure it costs less than $250.”

To survey the needs of those who will eventually use the device, Stevens returned to Rwanda in the summer of 2015 and met with device distributors to determine a manageable price point and desired specs. He then went to Nepal in the winter to visit remote hospitals and speak with staffs about their requirements.

Nurses were thrilled with the smaller form factor and extended battery life, and they were grateful to have a device that began measuring vitals as soon as it was turned on. Though there were a handful of requests for additional features, like loading bars that indicate FreePulse is “thinking,” staffers were almost universally happy with a product that could potentially solve a pressing problem in their community.

After improving the device based on this feedback, Stevens returned to Nepal the following winter, this time prepared to use FreePulse in a clinical setting. “It was important to show doctors the actual device,” he said. “You can talk about it all you want, but when someone holds it in their hands, it’s a lot easier to see what does or doesn’t work.”

“We didn’t have many tools. I had a knife and some epoxy, and I was gluing stuff together on bumpy jeep rides to keep it intact,” he said. “It was a dramatic experience that taught me how to take something that works in a lab and shape it so it works in an actual hospital. That’s where the doctors are judging your product—in the field.”

Stevens was excited to see his monitor in action but also found the experience to be somewhat stressful. No longer a visiting student providing maintenance as needed, Stevens now assumed full responsibility for the success or failure of his own device, which he continues to work on today.

He plans to have a clinic-ready prototype in 2018, and he hopes to return to hospitals in Nepal and leave fully functional monitors behind.

Stevens credits the Cockrell School of Engineering for providing both the opportunity to make these trips and the training and understanding he needed to react to the problems he encountered.

“I’m so grateful for my professors, all of whom were very supportive and encouraged us to continue past what they taught us,” he said. “Through projects and lab work, they provided a way to go far beyond the curriculum.”

After graduating in May 2017 with a bachelor’s degree in biomedical engineering, Stevens has reflected on his time in Texas Engineering and said he feels incredibly lucky to have been given so many opportunities.

“When I was growing up, my dad would always remind me, ‘To people who have been given much, much will be expected,’” Stevens said. “Because I have been helped by so many, I feel like it’s my turn to help as many as I can.”

Photos: Courtesy of Madeleine Dunaway